Brushless vs. Brushed DC Motors: Performance, Maintenance, and Cost Trade-offs

Key Takeaways

- Appropriate upkeep can prolong motor durability while efficiency plays a crucial role in practical uses.

- Examination of brushless motors in automation highlights their advantages, alongside professional perspectives on upcoming motor innovations.

How Can Proper Maintenance Extend Motor Lifespan?

Regular maintenance significantly impacts the lifespan of DC motors, whether brushed or brushless. For instance, brushed motors require periodic inspection and replacement of carbon brushes to prevent performance degradation. A well-maintained carbon brush motor can operate effectively for several thousand hours, while neglecting maintenance can drastically reduce that time. Cleaning the commutators and ensuring that the motor components are adequately lubricated also enhance operational efficiency and longevity.

For brushless motors, maintenance focuses on monitoring the electronic components and ensuring proper cooling. Regularly checking connections and ensuring software updates when applicable can help sustain optimal performance. Utilizing reliable suppliers, like a techtop authorized distributor, ensures access to high-quality components designed to minimize maintenance needs. Collectively, these practices not only prolong motor lifespan but also reduce downtime and increase overall efficiency in applications across various industries.

Best Practices for Brushed and Brushless Motors

Brushed motors require regular maintenance to ensure optimal performance. Routine inspections should focus on brush wear and commutator condition. For instance, operators using high-duty cycles may need to replace brushes every 500 to 1,000 hours to prevent sparking and efficiency loss. Lubrication is also key, as maintaining proper lubrication in these motors minimizes friction and heat generation, which can degrade motor components over time.

In contrast, brushless motors, such as those provided by techtop motors, offer different maintenance requirements. Their design inherently reduces wear by eliminating brushes. However, these motors still benefit from occasional inspections of bearings and electronic control systems to prevent overheating and component failure. Utilizing diagnostic tools can help identify performance issues before they escalate. By following these best practices, professionals can extend the lifespan of both brushed and brushless motor systems while enhancing overall performance and reducing downtime.

Why Does Motor Efficiency Matter in Real-World Applications?

Motor efficiency directly influences operational costs and performance metrics across various applications. For instance, brushless motors, known for their high efficiency ratings, can achieve operational efficiency levels exceeding 90% under typical load conditions. In contrast, brushed motors typically operate around 70% to 80% efficiency. This disparity results in greater energy consumption for brushed motors, leading to increased electricity costs and thermal management concerns, particularly in high-demand settings such as manufacturing and automotive systems.

Real-world applications illustrate the tangible benefits of motor efficiency. In robotics, companies utilizing techtop motors have reported significant energy savings, enabling longer run times and reduced heat generation, which enhances overall system longevity. Moreover, improved motor efficiency correlates with lower environmental impact due to reduced energy consumption, aligning with industry standards aimed at sustainability and energy conservation. As industries increasingly prioritize eco-friendly practices, selecting efficient motors becomes more critical in both reducing operational costs and adhering to regulations pertaining to energy usage.

Impact on Energy Consumption and Performance

Motor efficiency significantly impacts energy consumption and overall performance. Brushed DC motors typically operate at around 75-85% efficiency due to their inherent friction losses from brushes and commutators. In contrast, brushless DC motors can achieve efficiencies of 85-95%, primarily due to the absence of these components, which results in reduced mechanical wear and lower energy loss. For instance, a recent study found that implementing brushless systems in industrial fans led to a staggering 30% reduction in energy costs over a period of five years.

The enhanced efficiency of brushless motors translates directly to improved performance in real-world applications. When utilized in automation systems or robotics, these motors deliver faster response times and greater torque, scaling from low-speed applications to high-speed operations without compromising stability. With manufacturers like techtop motors offering advanced solutions, organizations can optimize energy usage while maintaining operational integrity. It is crucial for industry professionals to assess motor selection not just on upfront costs but also on long-term energy savings and performance output.

Case Study

Brushless motors have demonstrated significant advantages in robotics applications, particularly in terms of efficiency and lifespan. In a recent case study involving the integration of brushless motors into robotic arms used for precision tasks, data indicated an efficiency increase of up to 30% compared to traditional brushed counterparts. These advantages stem from the elimination of mechanical wear associated with brushes, allowing for smoother operations and reduced maintenance intervals. Furthermore, the controlled speed offered by brushless designs enhances the accuracy in intricate applications, such as assembly and surgical robotics.

The implementation of these motors also necessitated a comprehensive evaluation of energy consumption patterns. For example, a robotics company recorded a staggering 50% decrease in power use when transitioning to brushless models. This shift yielded not only lower operational costs but also supported sustainability efforts, aligning with industry standards for energy-efficient equipment. As a techtop authorized distributor, introducing high-performance motors like the tech top motors into various engineering projects can optimize performance and extend operational life, leading to more robust robotic solutions in the market.

Lessons Learned from Industry Implementation

The transition to brushless motors in robotics has revealed critical insights around reliability and efficiency. One notable case involved a leading robotics firm that integrated techtop motors into their assembly line. After a year of operation, the company reported a 25% increase in energy efficiency and a significant reduction in maintenance downtime. These improvements not only enhanced productivity but also validated the long-term cost savings associated with brushless technology as compared to traditional brushed models.

Companies deploying brushless motors have also learned about the importance of proper motor selection and application configurations. For instance, utilizing tech top motors allowed engineers to fine-tune torque output and speed settings in line with specific robotic tasks. This precision resulted in smoother operation and the minimization of wear-related failures. Adhering to industry best practices in installation and programming has emerged as a vital factor in harnessing the full potential of these advanced motors, reinforcing the need for collaboration with certified suppliers like a techtop authorized distributor.

- Understand the importance of energy efficiency in operational costs.

- Prioritize the selection of motors based on specific application requirements.

- Regularly review and optimize motor installation practices to ensure peak performance.

- Collaborate with certified suppliers to gain access to reliable resources and support.

- Monitor performance metrics closely to identify areas for improvement and innovation.

- Invest in staff training on the use and maintenance of brushless motors to maximize benefits.

- Stay informed on industry trends and advancements to maintain a competitive edge.

Expert Insights on Future Motor Technology

The evolution of motor technology hinges on several factors, primarily driven by efficiency and versatility. Tier-one manufacturers like Techtop Motors continue to push advances in brushless designs that minimize energy loss and enhance performance metrics. For example, recent data indicate that implementing brushless motors can improve efficiency by up to 25% compared to their brushed counterparts, particularly in applications requiring high torque at variable speeds. Furthermore, innovations such as integrated control systems enhance responsiveness and adaptability, critical for high-performance environments like robotics and electric vehicles.

Developments in materials science and digital control strategies are reshaping design paradigms. The move toward lightweight composite materials and advanced semiconductor technologies streamlines motor construction, improving thermal management and extending lifespan. Techtop authorized distributors emphasize that understanding the application-specific requirements and adhering to industry standards optimizes motor selection. Investing in advanced iterations of motor technology not only mitigates operational costs but also streamlines maintenance protocols, as fewer components can lead to reduced failure rates and increased system reliability. Hence, adopting these emerging trends is pivotal for businesses committed to maximizing operational efficiency and minimizing downtime.

FAQS

What are the main differences between brushless and brushed DC motors?

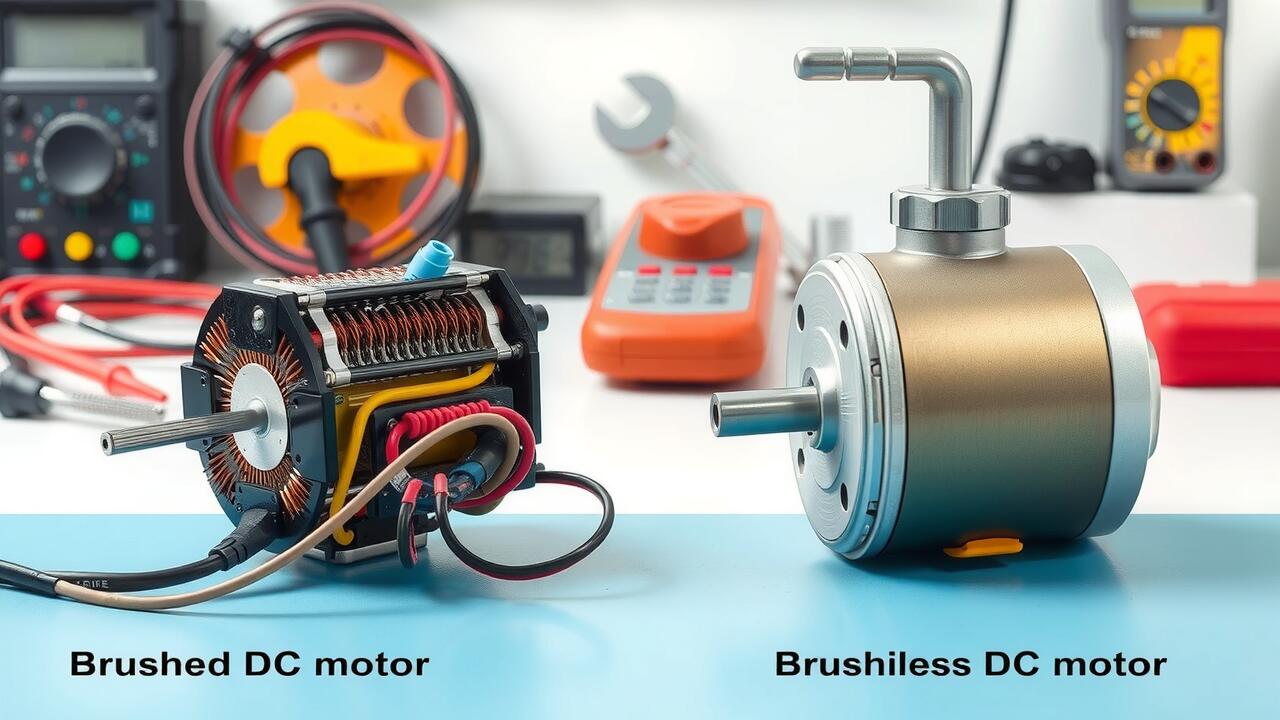

Brushless DC motors use electronic commutation instead of brushes, resulting in higher efficiency, lower maintenance, and longer lifespan, while brushed DC motors rely on mechanical brushes that can wear down, leading to reduced efficiency and increased maintenance needs.

How can proper maintenance extend the lifespan of a DC motor?

Regular maintenance, such as cleaning, lubrication, and timely replacement of worn components, helps prevent wear and tear, overheating, and electrical failures, thereby prolonging the operational life of both brushed and brushless DC motors.

Why is motor efficiency important in real-world applications?

Higher motor efficiency translates to reduced energy consumption, lower operational costs, and improved performance in applications, which is crucial for industries aiming to enhance productivity and sustainability.

What are some best practices for maintaining brushed and brushless motors?

For brushed motors, it is essential to regularly check brush wear and replace them as needed, while brushless motors require periodic inspection of the electronic components and ensuring proper cooling to maintain efficiency.

What insights can be gained from the application of brushless motors in robotics?

The case study highlights that brushless motors in robotics offer superior precision, reduced maintenance, and enhanced performance, demonstrating their advantages in high-demand applications where reliability and efficiency are critical.